Introduction

In an era where sustainability is no longer a choice but a necessity, industries are increasingly turning to renewable energy sources to power their operations. Among these sources, solar energy stands out as one of the most viable options, especially for factories and warehouses. The shift toward manufacturing solar energy isn’t just about reducing carbon footprints; it’s also about financial prudence, operational efficiency, and long-term sustainability. This comprehensive guide aims to navigate you through the complex world of industrial solar panels, providing insights on how to connect with leading suppliers in the industry.

The journey into the realm of solar energy for manufacturing begins with understanding the technology behind solar panels and their applications in various industrial settings. In this article, we will delve into everything from factory rooftop solar panels to commercial solar panel installation in the UK, discussing factors like costs, ROI, financing options, and more. By the end of this guide, you’ll have a robust understanding of how to make informed decisions regarding your transition to renewable energy.

Understanding Industrial Solar Panels

What Are Industrial Solar Panels?

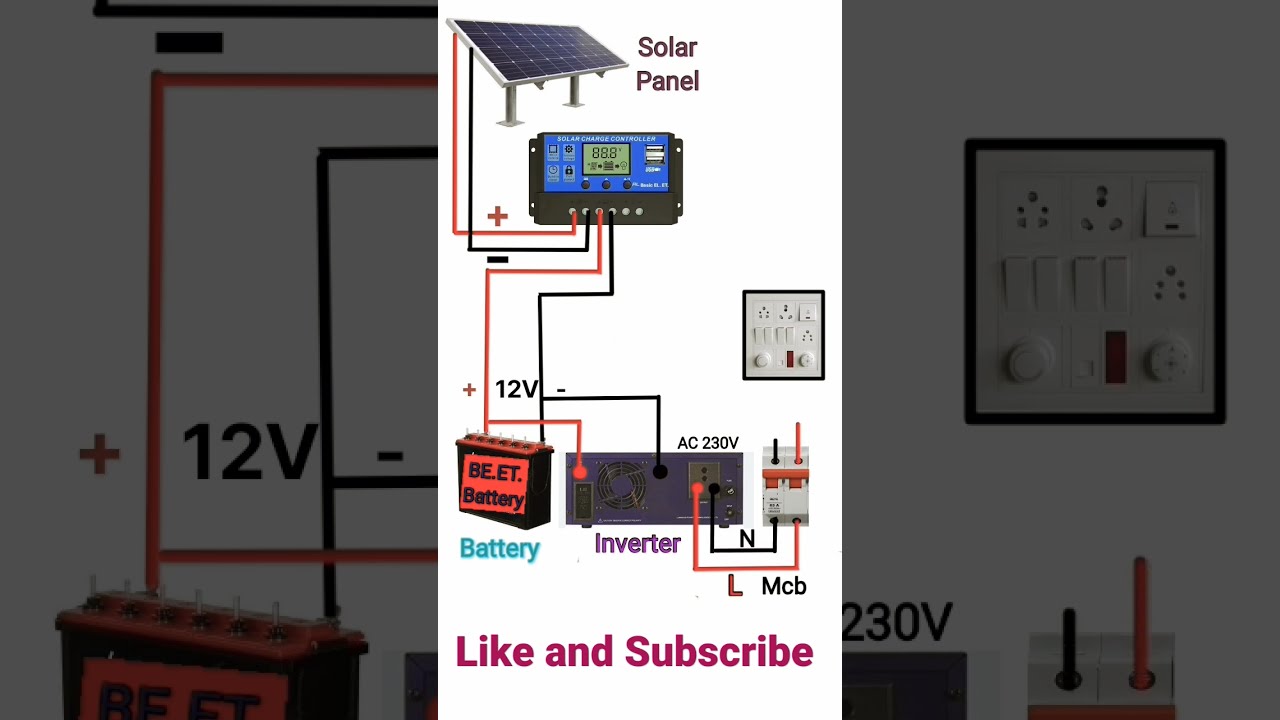

Industrial solar panels are specially designed photovoltaic (PV) systems that convert sunlight into electricity for industrial applications. These systems can vary significantly in size and capacity compared to residential solar panels. They’re engineered to meet the high energy demands of manufacturing facilities and warehouses.

Types of Industrial Solar Panels

Monocrystalline Panels: Known for their efficiency and longevity. Polycrystalline Panels: Generally less expensive but slightly less efficient than monocrystalline. Thin-Film Solar Panels: Lightweight and versatile but often less efficient than crystalline types.Benefits of Using Solar Panels in Factories

Cost Savings on Energy Bills

One https://essaymama.org/industrial-solar-monitoring-ensuring-optimal-performance/ of the most compelling reasons businesses are switching to industrial solar panels is the potential savings on electricity costs. By generating your own power, you can reduce reliance on grid electricity and mitigate rising energy prices.

Tax Benefits and Incentives

Many governments offer tax credits and incentives for businesses that invest in renewable energy solutions. These can significantly offset initial installation costs.

Enhanced Brand Image

Adopting sustainable practices not only helps save money but also enhances your brand image among consumers who prioritize eco-friendliness.

Choosing the Right Supplier

Researching Suppliers

When looking for industrial solar panel suppliers, it's crucial to conduct thorough research. Look for companies that specialize in factory installations and have experience in your specific industry.

Evaluating Supplier Credentials

Ensure that potential suppliers have proper certifications and licenses. Check their portfolios or case studies to gauge past performance.

Commercial Solar Panel Installation Process

Initial Consultation

The first step usually involves a consultation where suppliers assess your factory's energy needs.

Site Assessment

A physical inspection of your premises will help determine optimal placement for solar panels, considering roof orientation and shading.

Financing Options for Industrial Solar Projects

Upfront Costs vs Long-Term Savings

While initial investments may seem steep—sometimes reaching six figures—the long-term savings can far outweigh these costs through reduced electricity bills over time.

Leasing vs Purchasing

Some companies opt for leasing arrangements which require lower upfront payments but come with ongoing monthly fees. Others choose direct purchases aiming for long-term ownership benefits.

Understanding Factory Solar Panel Efficiency

Factors Affecting Efficiency Rates

Solar panel efficiency is influenced by several factors including sunlight exposure, angle of installation, temperature effects, and dust accumulation on panels.

| Factor | Impact on Efficiency | |--------------------------|---------------------------------| | Sunlight Exposure | Direct correlation with output | | Installation Angle | Optimal angles maximize gain | | Temperature | High temperatures can reduce efficiency | | Maintenance | Regular cleaning boosts output |

Solar Energy Management Systems (SEMS)

These systems monitor energy production from installed solar panels while optimizing energy consumption within factories. This ensures maximum efficiency is achieved throughout all operations.

Navigating Local Regulations

Every region will have advancements in solar power efficiency for factories its own set of regulations surrounding commercial solar installations:

Building Codes Zoning Laws Environmental RegulationsUnderstanding these regulations before initiating any projects can prevent unnecessary delays or penalties down the line.

Industrial Solar Energy Storage Solutions

As industries rely more heavily on renewable resources like solar power, having effective storage solutions becomes paramount:

- Battery Storage Systems Hybrid Systems

Case Studies: Successful Implementations of Industrial Solar Power Systems

Examining companies that successfully transitioned to using industrial solar systems provides valuable insights into feasibility:

- Company A: Reduced operational costs by 30% within two years. Company B: Achieved ROI within five years through strategic planning and government incentives.

FAQs About Connecting with Leading Industrial Solar Panel Suppliers

Q1: What is the average cost of installing factory solar panels?

The cost varies significantly based on panel type, installation complexity, local regulations, etc., averaging around £100K - £300K for large-scale installations in the UK.

Q2: How long does it typically take to install commercial rooftop solar?

Installation timelines can range from a few weeks up to several months depending on project scale and permitting processes.

Q3: Are there specific grants available for industrial companies considering solar?

Many regions offer grants or rebates aimed at encouraging businesses to adopt renewable technologies; consult local government resources or green initiatives organizations for details.

Q4: Can my factory operate entirely off-grid with a solar system?

Yes! With sufficient capacity from both generation & storage systems (like batteries), it’s feasible although it requires careful planning & investment initially.

Q5: What maintenance do commercial solar installations require?

Regular inspections ensure optimal performance; cleaning debris & monitoring system outputs are key components too!

Q6: Will switching to industrial solar affect my insurance premiums?

It could potentially lower premiums due to increased safety standards & reduced risk profiles associated with sustainable practices!

Conclusion

Transitioning towards using industrial solar panel systems is not merely an environmental endeavor; it’s also a financially prudent decision that has lasting impacts on operational efficiency while promoting sustainability within https://smoothdecorator.com/comparing-top-brands-in-the-global-market-from-an-industry-perspective/ industries worldwide—and connecting with leading industrial suppliers makes this journey simpler!

Whether you're exploring factory renewable energy options or seeking ways to cut down on energy expenses through manufacturing facility solutions—there’s never been a better time than now! By engaging qualified partners who understand both your needs as well as current trends shaping commercial power landscapes—you’ll be equipped with tools necessary not just thrive today but position yourself favorably tomorrow too!

In closing, investing in industrial solar power is more than just an upgrade; it's stepping into a future where sustainability meets profitability—a future every forward-thinking manufacturer should aspire towards achieving!